TEL:886-4 777 8698

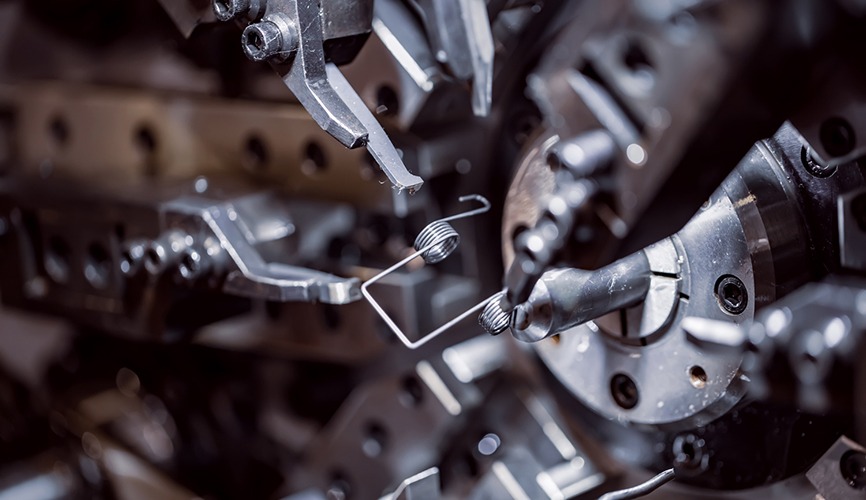

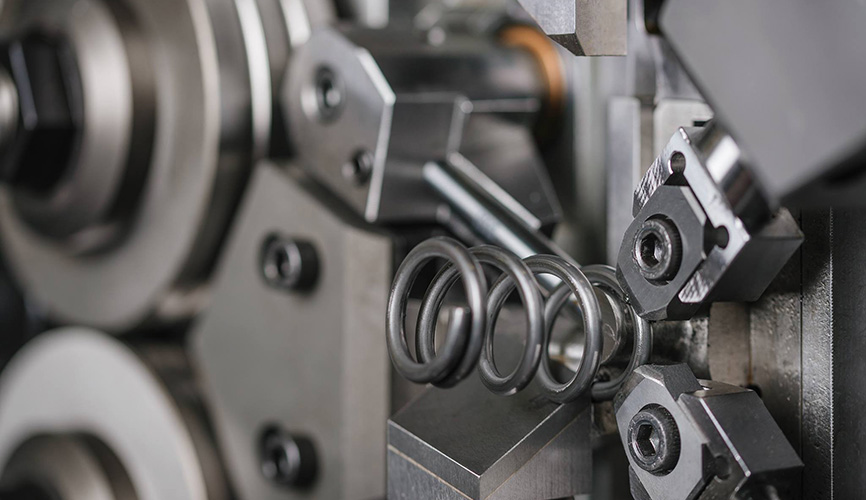

The company also invests in many professional testing instruments, with multi-axis full servo spring machinery, production modularization, to achieve professional precision, production efficiency improvement, reduce unnecessary costs, the price back to customers, to promote win-win profits and growth.

Piano steel wire、phosphor bronze wire with gold plating on surface、nickel plating.

Electronics industry: Probe spring, medical industry, can be designed and manufactured according to customer needs. Production is strictly controlled to ensure high quality.

MORE...

Medical springs are used in medical-related products,

many world-class sports brands, and provide the top-notch spring medical-related equipment support for you who are making progress every step of the way.

Compared with stainless steel, under the same design, the elastic modulus is 17% higher and the maximum stress. In addition, high carbon spring steel wire has better fatigue properties than stainless steel. Tight tolerance dimensional requirements produce smaller springs with greater rigidity. Meet the high precision and repeatability requirements of medical springs. Faster coil speeds, fewer machine cleanings, and less expensive thick plating.

MORE...

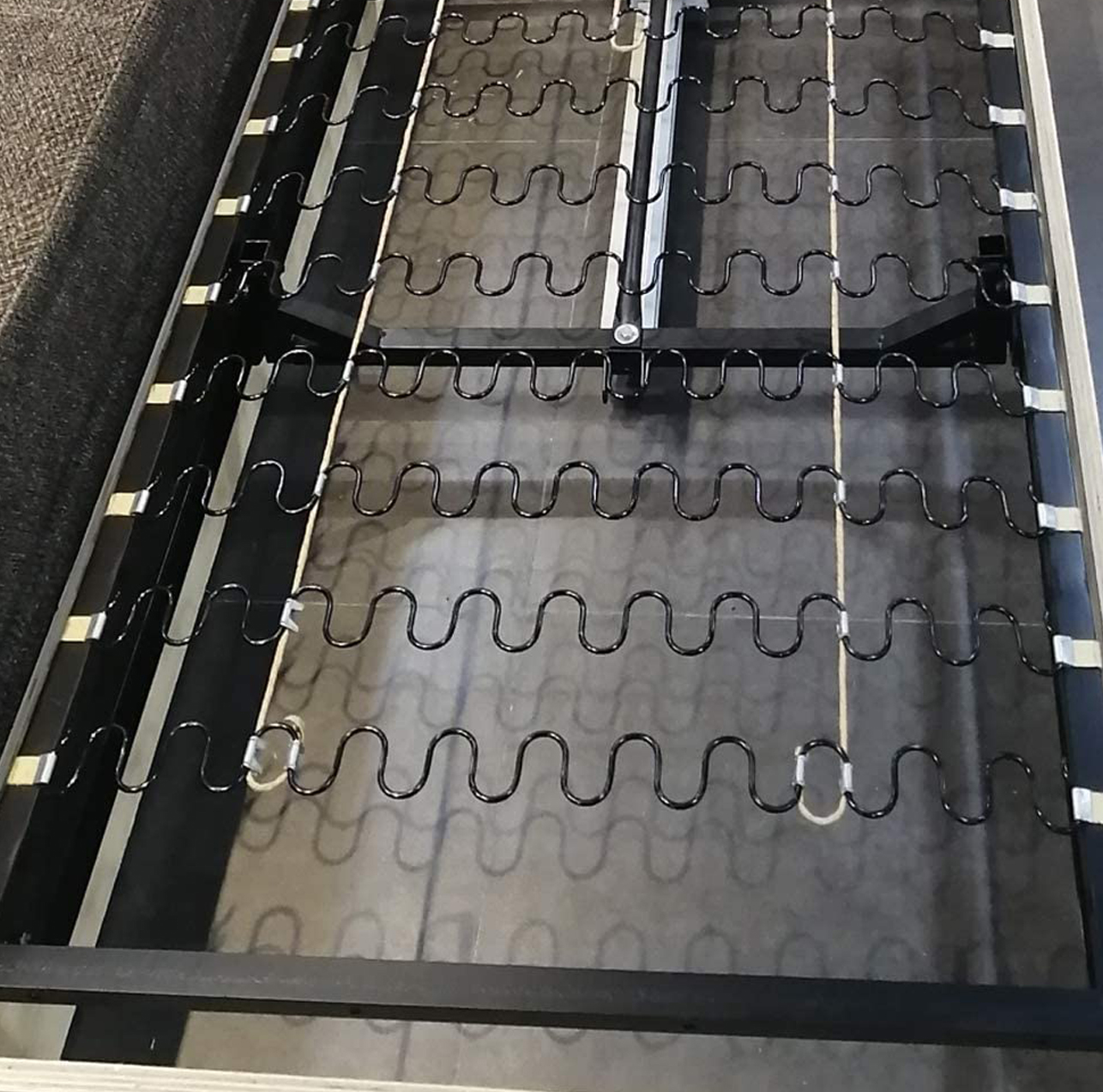

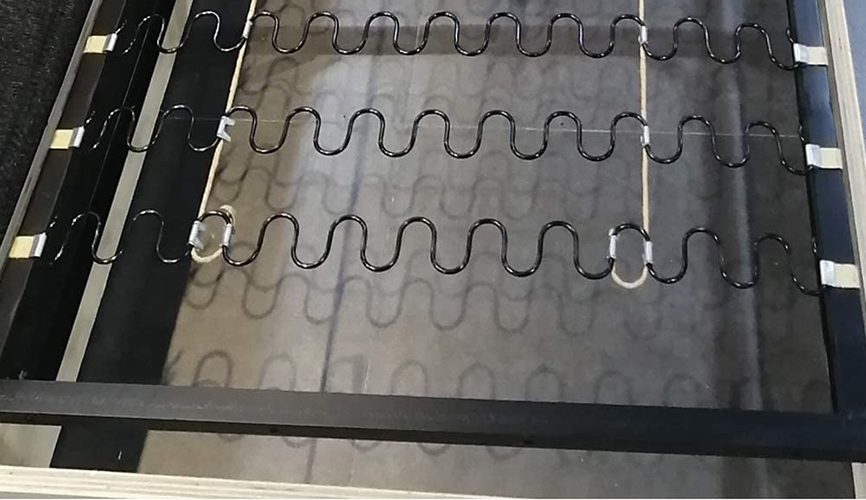

The range of wire materials includes stainless steel wire, piano steel wire, copper wire, flat wire, etc. Wire products manufacturing, such as all kinds of display stands, wire forming, hardware accessories, wire forming, wire processing products, racks, bathroom hardware, kitchen hardware supplies, and other decorative hardware, bathroom accessories, metal display stands, etc. They are all included in the processing range of hardware lines.

MORE...

Due to different materials, wire diameters, spring constants, heat treatment, etc. tension springs have different loads and lengths.

When the tension spring is not under tension, each circle is close together. Under tension, the weakest part of the tension spring is the place where the linear change is the largest. Most of the calculation formulas of the tension coil spring are that the tension load of the spring acts on the axis of the coil so the basic compression springs for the relationship between load-deflection and load-stress are exactly the same. The shape of the two ends of the tension spring can be classified into those that process the end of the spring into a hook and use other mounting accessories. The extension spring is essentially the same as the compression coil spring. The so-called design precautions here are aimed at the inherent problems of the tension spring—the deflection of the hook, the stress concentration and the initial tension, the shape of the parallel hook and the shape of the installation accessories, etc.

MORE...

Springs are made of various elastic materials. The most common is spring steel. Small springs can be wound from pre-hardened billets, while larger springs are made from annealed steel and hardened after fabrication. Some non-ferrous metals are also used in phosphor bronze and titanium for parts that require corrosion resistance and beryllium copper for springs that carry current (because of its low resistance).

MORE...

The main purpose of battery spring is to fix the position of the battery to avoid vibration or violent shaking, which may cause the power outage due to the disconnection of the contacts. There are many types of buckles. If they are classified by shape, the simple one is to roll the thread into a circle, and then use a punch to change the width, etc. There is no official name. For the inserter, most of the E-shaped clasps belong to the grooves in which the clasp is inserted into the shaft or hole, which prevents the movement of the shaft direction. Therefore, if there is insufficient strength for the thrust, the clasp will lose its meaning.

MORE...

The sheet shrapnel (spring sheet) is made of metal plate or steel strip. The elasticity is generated by the bending of the sheet shrapnel. It’s often used when the design space is limited but certain elasticity is required. In addition, simple sheet metal stamping parts made by spring machine molds cost less than those made of punch presses.

MORE...

Fasteners are screws and nuts, which are made of wire (disk element). They are called "the rice of industry". Fasteners can combine various parts into a unit or system, making the components easy to assemble or disassemble. The components form a complete object through the locking function of screws and nuts, which facilitates the process of assembly, repair, replacement and reassembly.

MORE...